Safe, self-contained nitrogen pumping and vaporizing systems for off-shore

drilling and in-plant nitrogen servicing operations especially suited to

severe climates.

|

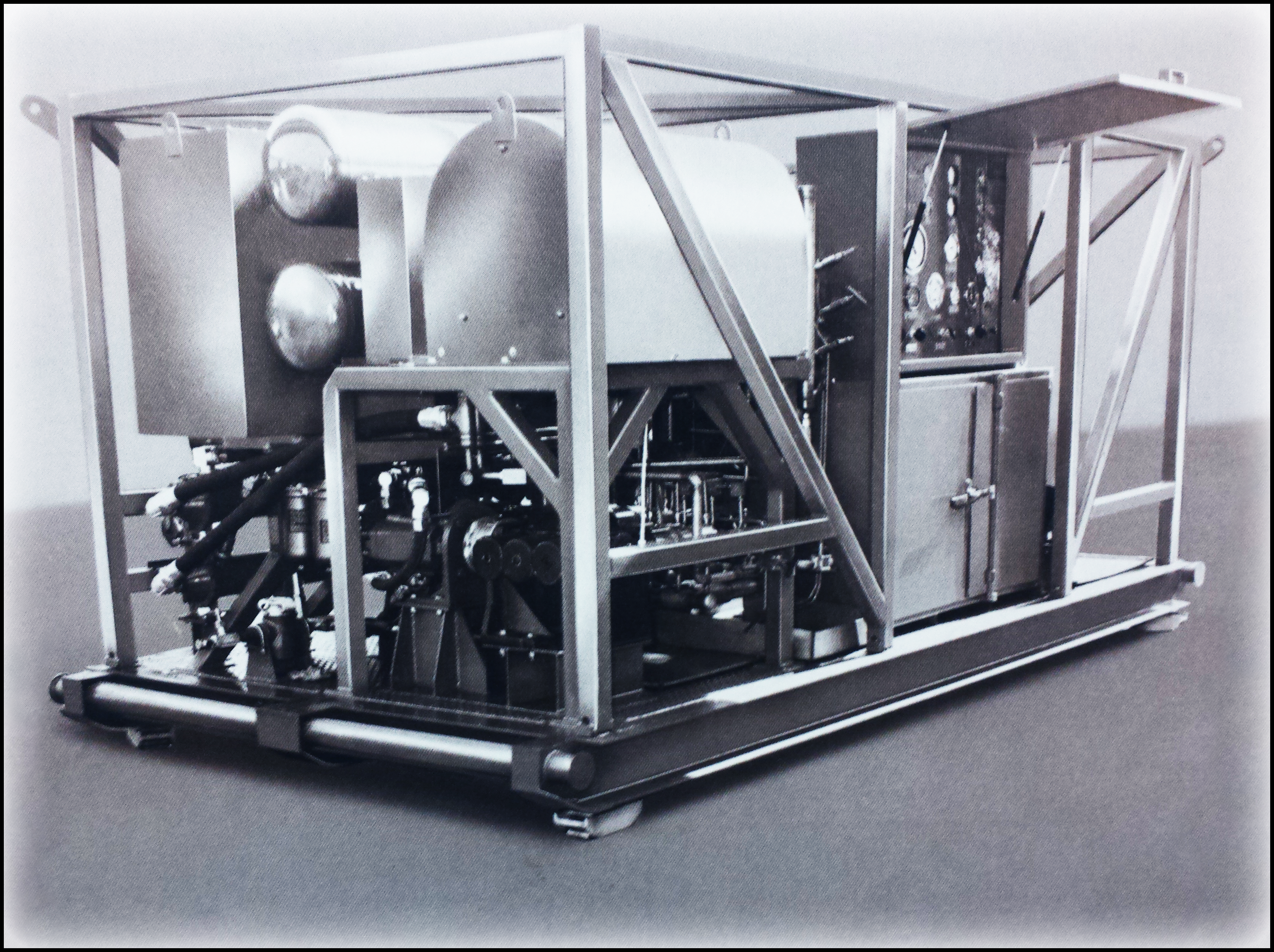

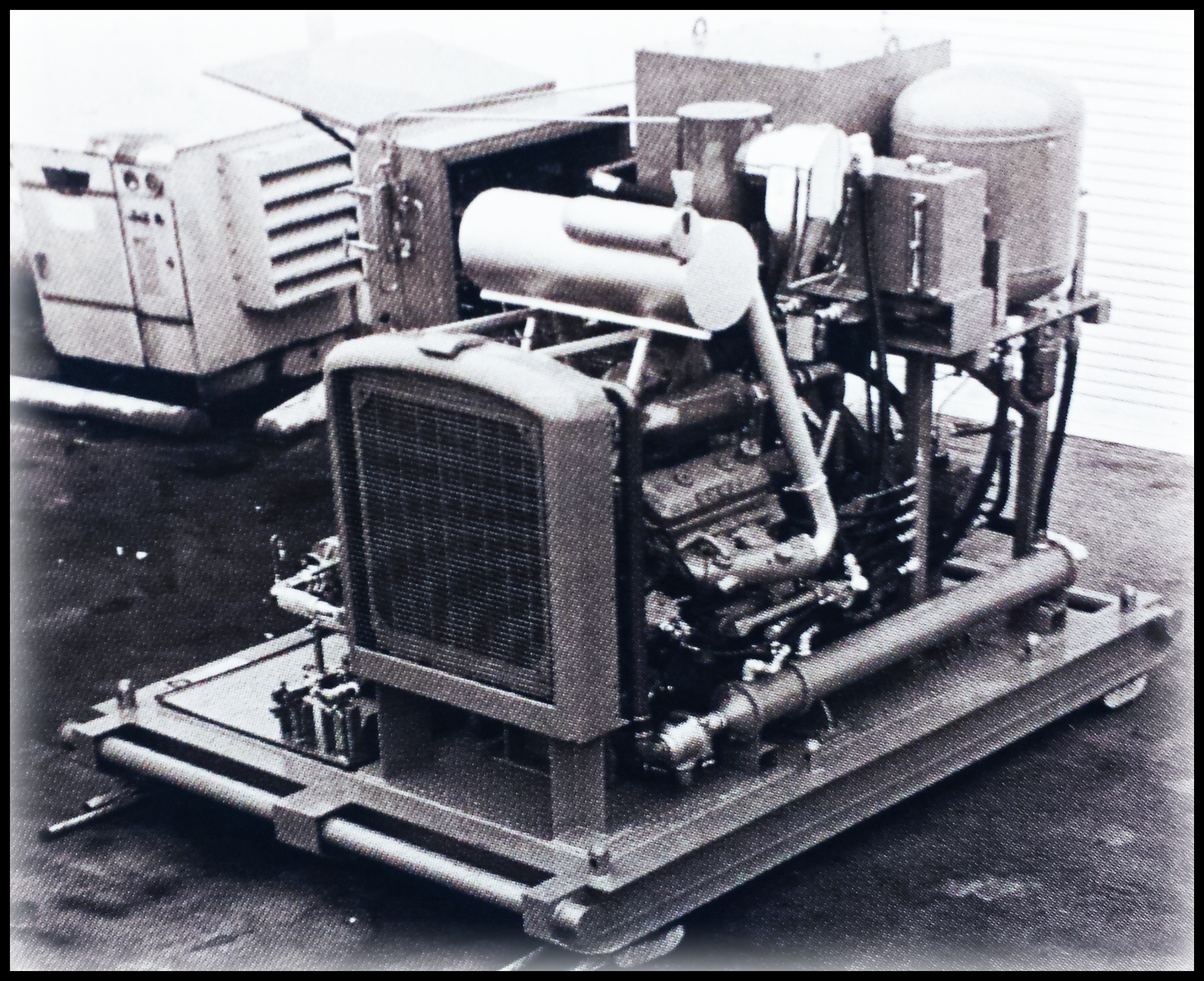

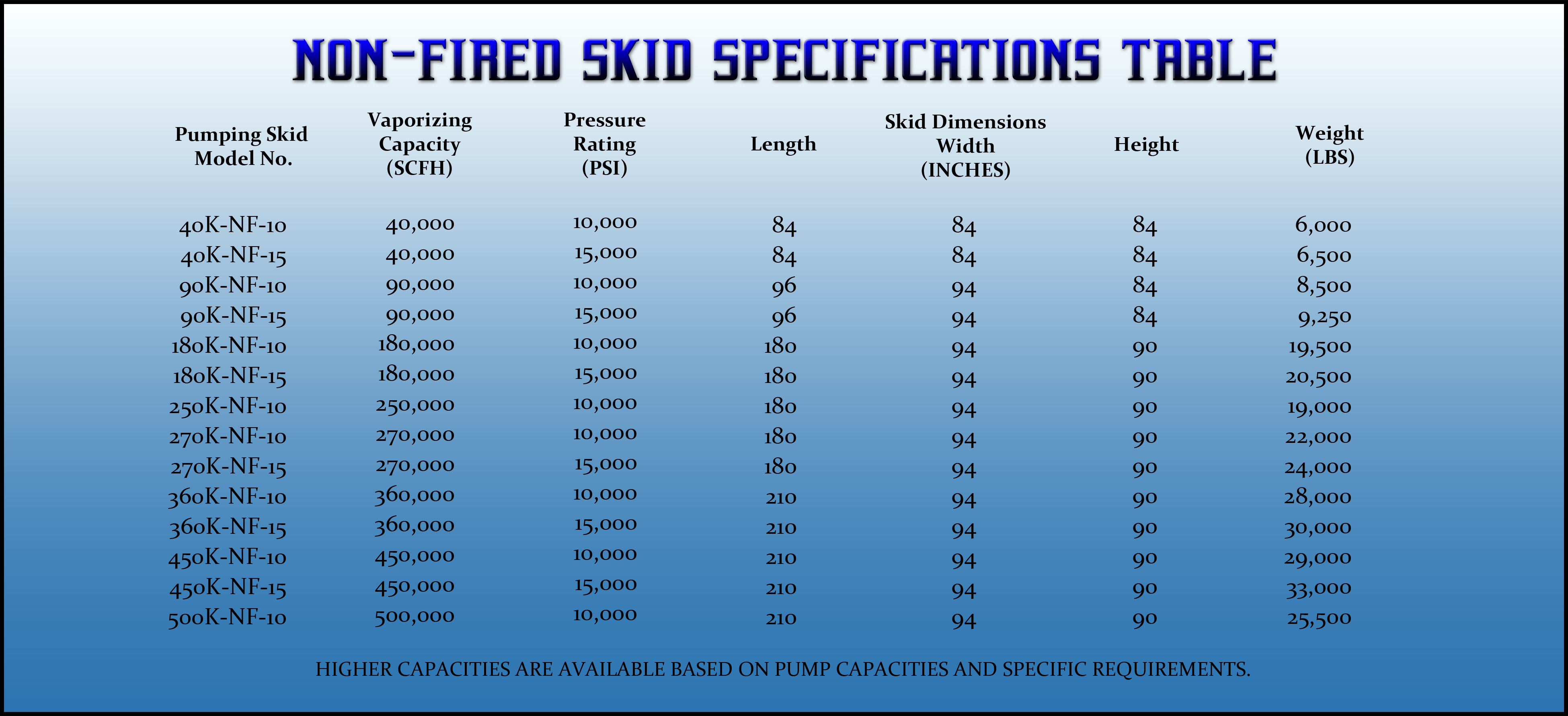

DK Aerospace & Industrial Non-Fired Pumping Skids were developed in response to the increasingly urgent demand for safe, reliable delivery of gaseous nitrogen required for efficient oil recovery and similar operations in hazardous locations and under severe climactic conditions. These rugged, self-contained units pump and vaporize liquid nitrogen, producing from 40,000 to 500,000 SCFH of gas at pressures up to 15,000 psi and temperatures from 70 to 135F. They have three main advantages over other types of nitrogen pumping and vaporizing equipment commonly used for oil well and industrial nitrogen servicing: - They are extremely easy to operate and maintain. - They are inherently safe because they are non-fired. - They perform flawlessly at the extreme temperatures encountered in the Arctic and North Sea (unlike ambient-air heated systems) The basic components of all DK non-fired systems are a diesel engine-driven hydraulic pump, a high-pressure nitrogen vaporizing heat exchanger, a low-pressure heat exchanger for cooling the hydraulic oil, and a centrifugal pump to prime the main cryogenic pump. Unique Non-Fired Heating All of the heat required for nitrogen vaporization in the DK non-fired unit is supplied by the diesel engine. The patented system design uses a balance of components and simple controls to automatically match the available engine heat to the nitrogen flow rate. DK Aerospace & Industrial non-fired systems do not rely on ambient air for vaporization. These units can operate anywhere that a diesel engine can; even under the extreme low temperature ambient conditions found in the North Sea and Arctic. Simple Start-Up and Operation DK pumping and vaporizing units are extremely simple to operate. After the diesel engine is warmed up, the cryogenic components are cooled by liquid nitrogen to operating temperature. The centrifugal pump is started (if necessary) and the main pump is primed. The engine is then set at rated operating speed, and the LN2 flow-rate control is moved to the desired setting. The nitrogen discharge temperature will normally be in the range of 130F-160F. A tempering valve is provided which can bypass sufficient LN2 to cool the pump discharge to 70F. |

Automatic Features Once system operation has been properly initiated, no further manual control is necessary except for adjusting the LN2 pump rate to the desired flow. The engine governor holds the engine speed constant, and the inherent heat balance of the system keeps the LN2 discharge temperature nearly constant. The flow of coolant through the engine radiator is controlled by a thermostatic valve which provides the cooling the engine requires when it is not heating nitrogen. Simple Maintenance For all of their rugged sophistication and automated design, DK pumping and vaporizing systems are remarkably easy to maintain. All hydraulic components are self-lubricating and the sealed shell-and-tube heat exchangers require no servicing. The only maintenance procedures normally required are routine inspection and servicing of hydraulic filters and normal diesel engine maintenance. |

If you are interested in purchasing this product, please contact us.