Benefits

• Reliable • Double Acting • Self-Lubricating Air Drive • Portable • Economical • Non-Electrical • Oil-Free |

Functions • Injection Molding • Blanketing • Drying • Purging • Product Transfer Applications • Breathing Air • Arc Suppression |

General Information

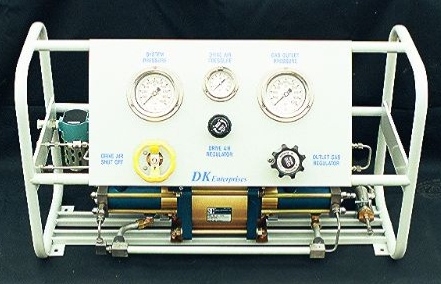

DK Aerospace & Industrial's air driven gas booster systems are self-contained units, using cycling spools and pilot valves to provide automatic reciprocating action when air or gas is supplied to the air drive inlet. Our boosters are powered and controlled by the pressurized air or gas supply, with no electrical connections. The drive consists of a large piston and valve assembly directly connected to hydrocarbon-free dual pumping pistons, with self lubricating seals cycling in stainless steel barrels that have integral check valves. The working surface area of the drive piston exceeds the working surface area of the pump piston, thereby providing pressure BOOST. This is accomplished by using relatively low pressure air or gas to the drive inlet. The air drive section is pre-lubricated (thus eliminating the need for an air line lubricator), and easy to install. DK gas booster systems are typically used to boost low pressure gas/air from a gas cylinder to a higher pressure required at the process or test station. Most industrial gases (nitrogen, helium, hydrogen, argon, oxygen, breathing air, etc.) are commonly delivered under pressure at 2,000 psi to 2,600 psi in steel cylinders. If the gas is to be used at low pressures, e.g., welding, the pressurized supply is easily piped and controlled to the point of use with simple valving. However, if the end use requires the gas under pressure, the supply cylinder pressure cannot be utilized after it has fallen to the level of the end use pressure. Therefore, the gas remaining will be wasted unless it is boosted. If the application requires a pressure greater than common supply cylinder pressure, a gas booster must be used. Depending on which Gas Booster System is selected, you can boost gas pressure from 300 psi to 20,000 psi. DK gas booster systems have other applications such as bottle filling from nitrogen generators and dewars, hydrogas suspension systems, automotive air gas storage systems, aircraft slide chute gas storage: Sulfur Hexaflouride transfer for arc suppression and insulation of circuit breakers commonly found in the Utility Industry, breathing air for scuba diving, gas injection molding, etc.

If you are interested in purchasing this product, please contact us.